The mission to net-zero flight calls for revolutionary thinking on all fronts: new, sustainable power sources, fuel-sipping engines, more direct routes through the air – and aircraft designs so sleek, they slash the energy needed to travel at jet speeds.

These futuristic designs are already in the works with Bombardier’s EcoJet Research Project – just one sign of how business aviation is at the forefront carbon-cutting innovation.

EcoJet is a long-term research effort, begun by the Montreal-based jet manufacturer 15 years ago, with the goal of halving carbon emissions from business aircraft. Among a host of other innovations, the project aims to reimagine the shape of a business jet – the airframe – to be radically more aerodynamic.

More aerodynamic means more energy efficient, and a lower carbon footprint. As represented by the CLIMBING. FAST. initiative, the global business aviation industry is committed to achieving net-zero emissions by 2050.

“Bombardier sees a sustainability mindset as inseparable from business growth. The bold promise we’ve made to be in a different place in the coming decades, the technology needed to get there, and our drive to be leaders of sustainability have pushed us to take this big leap,” said Bombardier’s Senior Vice President of Engineering and Product Development Stephen McCullough. “We are acting on many fronts to improve the environmental footprint of our products, and developing a radically different aircraft configuration while continuing to meet and exceed our clients’ expectations is one of our north stars in this long-term commitment.”

“Bombardier sees a sustainability mindset as inseparable from business growth. The bold promise we’ve made to be in a different place in the coming decades, the technology needed to get there, and our drive to be leaders of sustainability have pushed us to take this big leap.”

Stephen McCullough, Senior Vice President of Engineering and Product Development, Bombardier

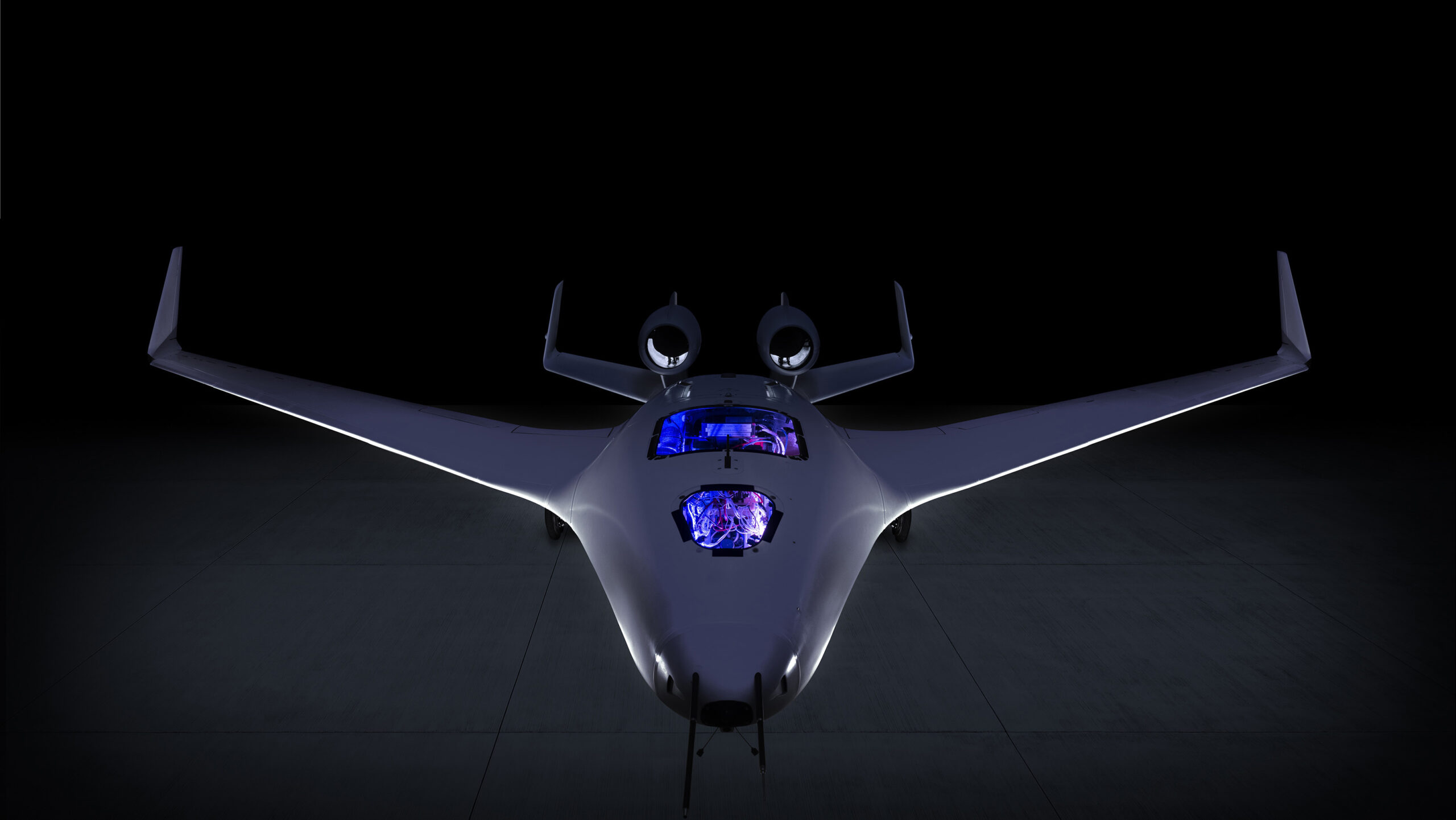

After years of theoretical modeling and wind tunnel trials, Bombardier first tested a small-scale prototype leveraging the new design, a configuration called a blended wing body (BWB), in 2017. The EcoJet Research Project is now in its second testing phase, flying an 18-foot-wingspan demonstrator vehicle that can fly higher, faster and longer than the first model.

The Climate Game-Changer: Blended Wing Body Design

Bombardier calls the EcoJet design “the future of business aviation.” The way the wings are ‘blended’ into the fuselage reduces drag. The smooth sweep of the fuselage itself creates lift, reducing the size of the wings and improving fuel economy.

Recent advances in computer modeling and composite materials make the BWB design achievable. While we have decades of information into how traditional tube-and-wing airframes perform, Bombardier engineers know we have a lot to learn about how a BWB business jet would fly.

That is what the second-phase, 18-foot demonstrator aircraft, is testing at undisclosed locations in North America.

“With the EcoJet Research Project, Bombardier has intentionally put itself in a situation to drive rapid learning and to grow, flying not only new configurations but also building an entirely new methodology.”

Stephen McCullough, Senior Vice President of Engineering and Product Development, Bombardier

“With the EcoJet Research Project, Bombardier has intentionally put itself in a situation to drive rapid learning and to grow, flying not only new configurations but also building an entirely new methodology,” said McCullough. “EcoJet must be seen as a journey: it started with a vision and a science-driven mindset to transform the industry and it continues to progress, step-by-step, from the original ideas.”

The Phase 2 model first flew in 2022 and was unveiled at the European Business Aviation Convention & Exhibition (EBACE) the following year. Radio controlled, with autonomous flight capabilities, the demonstrator has completed more than a dozen test flights, gathering data and telemetry for Bombardier’s engineers.

Cutting Business Jet Emissions in Half

The EcoJet Research Project is a clear sign of business aircraft manufacturers’ commitment to the industry’s net-zero goals – and the kind of radical innovation it will take to achieve them. Bombardier estimates the EcoJet research will eventually make it possible to cut business jet emissions by 50%.

The aerodynamics of the BWB design alone could reduce emissions by 20%, renewable fuels and other advances in propulsion could cut another 20% and the remaining 10% could be achieved with weight-saving techniques, advanced materials and other technologies.

A future business jet with the BWB design could be fueled by sustainable aviation fuel, but also by alternatives, such as hydrogen.

“The potential to deliver an assortment of new technology for the short-, mid- and long-term is the beauty of Bombardier’s EcoJet project,” said McCullough. “In our journey to create more sustainable aircraft, we are looking at innovation holistically. Aerodynamics simulation, structural optimization, alternative propulsion architecture are examples of fields we are looking into, with our industrial and academic partners, many elements which may at some point benefit our in-service fleet.”

In early 2024, Bombardier announced the first of many partners on the EcoJet Research Project: the University of Victoria’s Centre for Aerospace Research and Quaternion Aerospace. Both British Columbia-based organizations have expertise in building scale models and have participated in the first two phases of the EcoJet program.

Rapid Prototyping for New, Sustainable Aircraft

The small size of the demonstrator aircraft allows Bombardier to make modifications easily, trying out new design concepts, for faster iteration. The Phase 1 vehicles had an 8-foot wingspan and were about 7% the size of a long-range business jet. The larger Phase 2 model includes more of the internal subsystems of a real jet.

EcoJet is not an aircraft program, such as Bombardier’s Challenger or Global family of business jets and does not follow the same objectives and validation routes as traditional product flight-test programs. That gives engineers the freedom to prove technologies that could yield fuel savings for future models of Challenger or Global jets, but also give birth to entirely new engineering, for the more sustainable, hyper-efficient business aircraft of the future.